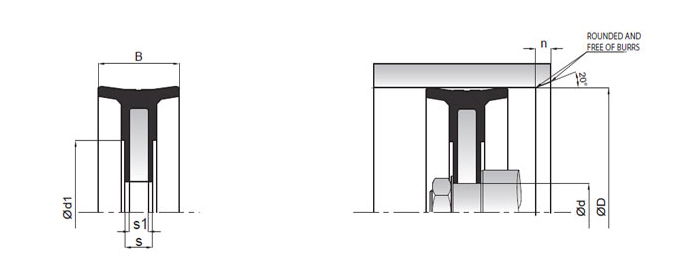

K25 is a double acting complete piston seal which consists of a steel plate vulcanized with elastomeric nitrile rubber using special production methods.

PRODUCT ADVANTAGES

• Ready to fit complete piston

• Wide range of dimensions

• Low friction and smooth running due to sealing lip

geometry

• Easily fastened to the piston rod without using additional

sealing elements

• Long service life

• Economical sealing solution

APPLICATION

Iron and aluminum pneumatic cylinders.

| MATERIAL | CODE | ||

| NBR | 75 SHORE A | NB7501 | |

| STEEL | ST37 | FE9901 |

|

MEDIA |

Prepared , dried and de-oiled compressed air |

| TEMPERATURE | -30°C +105°C |

| PRESSURE | ≤16 Bar |

| SPEED | ≤1.0 m/sn |

|

SURFRACE ROUGHNESS |

Rmax | |

| Sliding Surface Ød | ≤0.4 μm | ≤3.2 μm |

INSTALLATION

K25 is pushed onto the piston rod on the clamping flange towards the rod and fixed by fastening. The nut has to be secured. The sliding surface and the cylinder bore should be oiled with oil that must not go into the reaction with the sealing element during the installation process. Special precautions has to be taken at the end of the stokes to avoid damaging of the sealing lips.

NOTES

For special applications that require high temperatures , K25 can be produced in FKM material.

| KASTAŞ NO | D (H11) | d (h9) | B | d1 | s1 | s |

|---|---|---|---|---|---|---|

| K25-020 | 20 | 5,2 | 8 | 12,2 | 1 | 1,4 |

| K25-025 | 25 | 8 | 12 | 14,5 | 3 | 4 |

| K25-025/2 | 25,4 | 6,35 | 12,7 | 9,40 | 2,5 | 3,50 |

| K25-026 | 26 | 8 | 12 | 15,5 | 3 | 4 |

| K25-028 | 28.58 | 6.35 | 12.7 | 12.58 | 2.5 | 3.5 |

| K25-031 | 31.75 | 6.35 | 14.29 | 15.75 | 2.5 | 3.5 |

| K25-032 | 32 | 8 | 15 | 16 | 3 | 4 |

| K25-035 | 35 | 8 | 15 | 19 | 3 | 4 |

| K25-036 | 36 | 8 | 15 | 20 | 3 | 4 |

| K25-040 | 40 | 10 | 18 | 23 | 4 | 5 |

| K25-044 | 44,45 | 6,35 | 14,28 | 23,46 | 2,5 | 3,50 |

| K25-050 | 50 | 10 | 18 | 29 | 4 | 5 |

| K25-050/2 | 50 | 16 | 20.5 | 25 | 4 | 5 |

| K25-050/7 | 50.8 | 9.53 | 15.88 | 15.75 | 3 | 4 |

| K25-057 | 57.15 | 9.53 | 15.88 | 34.65 | 3 | 4 |

| K25-060 | 60 | 12 | 22 | 36,8 | 4 | 5 |

| K25-060/1 | 60.33 | 9.53 | 15.88 | 37.83 | 3 | 4 |

| K25-062 | 62 | 15 | 22 | 39 | 5 | 6 |

| K25-063 | 63 | 12 | 22 | 40,5 | 5 | 6 |

| K25-069 | 69.85 | 9.53 | 19.05 | 47.35 | 4 | 5.5 |

| K25-070 | 70 | 12 | 22 | 47 | 5 | 6 |

| K25-073 | 73.03 | 9.53 | 19.05 | 48.03 | 4 | 5.5 |

| K25-075 | 75 | 15 | 22 | 52 | 5 | 6 |

| K25-075/1 | 75 | 12 | 22.5 | 52 | 5 | 6 |

| K25-076 | 76.2 | 12.7 | 19.05 | 51.2 | 4 | 5 |

| K25-080 | 80 | 16 | 25 | 55 | 5 | 6,5 |

| K25-080/4 | 80 | 16 | 22.5 | 55.2 | 5 | 6.5 |

| K25-080/5 | 80 | 20 | 22,5 | 55,2 | 5 | 6,5 |

| K25-082 | 82.55 | 12.7 | 19.05 | 57.55 | 4 | 5 |

| K25-088 | 88.9 | 12.7 | 22.23 | 63.9 | 5 | 6 |

| K25-090 | 90 | 16 | 25 | 65 | 5 | 6,5 |

| K25-100 | 100 | 16 | 25 | 75 | 5 | 6,5 |

| K25-100/4 | 100 | 12 | 25 | 75 | 5 | 6.5 |

| K25-100/6 | 100 | 20 | 26 | 75 | 5 | 6.5 |

| K25-107 | 107.95 | 12.7 | 22.23 | 82.96 | 5 | 6 |

| K25-110 | 110 | 18 | 25 | 85 | 6 | 7,5 |

| K25-114 | 114.3 | 19.05 | 22.23 | 79.3 | 5 | 6 |

| K25-125 | 125 | 20 | 30 | 90 | 8 | 10 |

| K25-125/1 | 125 | 20 | 26 | 90 | 6 | 7.5 |

| K25-127 | 127 | 19.05 | 25.4 | 92 | 6 | 7.5 |

| K25-130 | 130 | 20 | 29 | 95,00 | 8 | 10,00 |

| K25-140 | 140 | 20 | 30 | 95 | 10 | 12 |

| K25-150 | 150 | 20 | 30 | 105 | 10 | 12 |

| K25-152 | 152.4 | 19.05 | 25.4 | 107.4 | 6 | 7.5 |

| K25-160 | 160 | 27 | 31 | 115 | 10 | 12 |

| K25-165 | 165.1 | 19.05 | 25.4 | 120.1 | 6 | 7.5 |

| K25-180 | 180 | 27 | 31 | 135 | 10 | 12 |

| K25-190 | 190 | 20 | 30 | 160,4 | 10 | 12 |

| K25-200 | 200 | 27 | 35 | 150 | 12 | 15 |

| K25-200/5 | 200 | 30 | 35 | 150,00 | 8 | 10,60 |

| K25-202 | 202.2 | 31.75 | 38.1 | 150.5 | 10 | 11 |

| K25-250 | 250 | 30 | 35 | 200 | 12 | 16,5 |

| K25-253 | 253 | 44.45 | 41.27 | 180 | 12 | 15 |

| K25-320 | 320 | 36 | 40 | 278,5 | 15 | 18,6 |

| K25-400 | 400 | 40 | 50 | 320 | 20 | 23 |