KX is a double acting X-ring with special design lip to be used both for rod and piston applications.

PRODUCT

ADVANTAGES

• Can be used both for reciprocating and rotating hydraulic

applications

• Low friction compared to o-rings

• No tool parting line on the dynamic surface

• No twisting in the groove

• Both for rod and piston application

• Economical sealing solution at low pressures

APPLICATION

Hydraulic and pneumatic valves , light duty cylinders , flanges and

heavy duty applications.

| MATERIAL | CODE | |

| NBR | 70 SHORE A | NB701 |

OPERATING CONDITION |

|||

| MEDIA | Mineral oils(DIN 51524) | HFA and HFB | HFC |

| TEMPERATURE | -30°C +105°C | +5°C +60°C | - 30°C +60°C |

| SPEED | ≤0.5 m/sn | ≤0.5 m/sn | ≤0.5 m/sn |

|

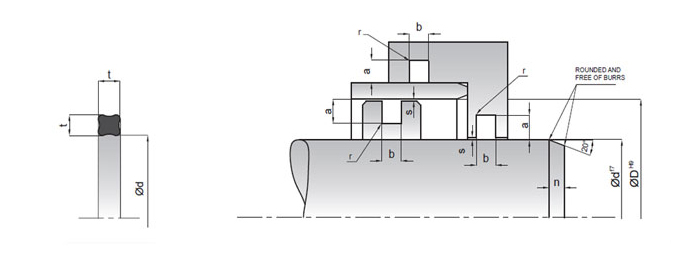

SURFRACE ROUGHNESS |

Ra |

Rmax |

| Sliding Surface Ød | ≤0.6 μm | ≤3.2 μm |

| Groove Base ØD | ≤2.5 μm | ≤10 μm |

| Groove Flanks B | ≤5 μm | ≤18 μm |

INSTALLATION

X-ring is assembled into the groove by hand. It is very important

that the assembly tools must be of soft material and have no sharp

edges. Before installation the seal must be oiled with system oil.

system oil.

NOTES

For special applications that require high temperatures, KX can be

produced in FKM. It can be used up to 400 bar with a back-up ring.

| KASTAŞ NO | d | t | astatik | adinamik | b (-0/+0,2 | r | s |

|---|