tel. 33 814 56 92

K98 is a single acting piston - rod

seal and designed to have symmetrical lips in order to be used both

for rod and pistonapplications. O-ring acts as a spring and

provides sealing contact under low pressures and shock

pressures.

PRODUCT ADVANTAGES

• Good sealing performance under low pressures and shock

pressures

• Superior static and dynamic sealing effect

• Easy assembly into closed grooves

• Simple groove design

• Economical sealing solution

APPLICATION

Fork-lift trucks , injection moulding machines , agricultural

machinery and standard cylinders.

| MATERIAL | CODE | |

| NBR | 70 SHORE A | NB7001 |

| PU | 92 SHORE A | PU9201 |

| OPERATING CONDITION | |||

| PU | |||

| MEDIA | Mineral oils(DIN 51524) | HFA and HFB | HFC |

| TEMPERATURE | -30°C +100°C | +5°C +50°C | -30°C +40°C |

| PRESSURE | ≤400 Bar | ≤400 Bar | ≤400 Bar |

| SPEED | ≤0.5 m/sn | ≤0.5 m/sn | ≤0.5 m/sn |

|

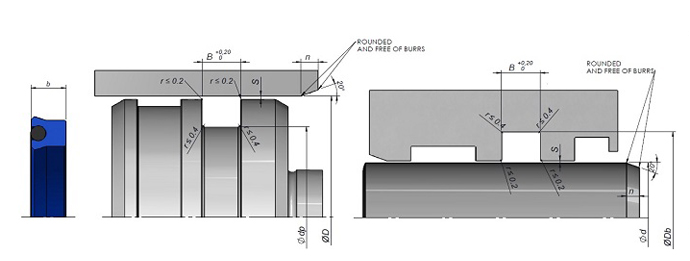

SURFRACE ROUGHNESS |

Ra |

Rmax |

| Sliding Surface ØD-Ød | ≤0.4 μm | ≤3.2 μm |

| Groove Base ØDb-Ødp | ≤1.6 μm | ≤10 μm |

| Groove Flanks B | ≤3.2 μm | ≤16 μm |

| MINUMUM DIAMETER VALUES FOR CLOSED TYPE OF GROOVES | ||||||||

| (D-d)/2 (mm) | 4 | 5 | 6 | 7.7 | 10 |

| 12.5 | 15 |

| dmin (mm) | 25 | 30 | 40 | 50 | 80 |

| 100 | 105 |

| PERMISSIBLE SEALING GAP | |||

| t=(D-d)/2 | 150 Bar | 250 Bar | 400 Bar |

| TEMPERATURE | -30°C +105°C | +5°C +60°C | -30°C +60°C |

| t≤5 | 0.30 | 0.20 | 0.15 |

| t>5 | 0.35 | 0.25 | 0.20 |

| KASTAŞ NO | d(f7) dp(h11) | Db(H11) D(H11) | B (-0/+0,2) | n |

|---|---|---|---|---|

| K98-019 | 19,05 | 25,4 | 6,98 | 3 |

| K98-022 | 22,23 | 28,58 | 3,51 | 3 |

| K98-025 | 25,4 | 31,75 | 6,98 | 3 |

| K98-025/1 | 25,4 | 34,93 | 5,28 | 4 |

| K98-025/2 | 25,4 | 34,93 | 8,71 | 4 |

| K98-025/3 | 25,4 | 38,1 | 6,98 | 4,5 |

| K98-031 | 31,75 | 38,1 | 6,98 | 3 |

| K98-031/1 | 31,75 | 41,28 | 8,71 | 4 |

| K98-038 | 38,1 | 47,63 | 8,71 | 4 |

| K98-038/1 | 38,1 | 47,63 | 10,49 | 4 |

| K98-038/2 | 38,1 | 50,8 | 10,49 | 4,5 |

| K98-044 | 44,45 | 53,98 | 10,49 | 4 |

| K98-050 | 50,8 | 60,33 | 10,49 | 4 |

| K98-050/1 | 50,8 | 63,5 | 10,49 | 4,5 |

| K98-057 | 57,15 | 69,85 | 6,98 | 4,5 |

| K98-063 | 63,5 | 76,2 | 10,49 | 4,5 |

| K98-076 | 76,2 | 88,9 | 10,49 | 4,5 |

| K98-088 | 88,9 | 101,6 | 10,49 | 4,5 |

| K98-092 | 92,08 | 101,6 | 10,49 | 4 |