tel. 33 814 56 92

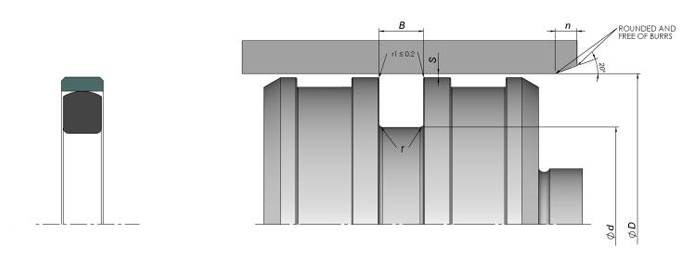

K755 is a two piecedouble acting

piston seal which consists of one energizing elastomer ring and

special mixture thermoplastic ring.

PRODUCT ADVANTAGES

| MATERIAL | CODE | |

| PTFE | PT6003 | |

| NBR | 90 SHORE A | NB8001 |

OPERATING CONDITION |

||

| MEDIA | Mineral oils(DIN 51524) | |

| TEMPERATURE | -30°C +105°C | |

| PRESSURE | ≤400 Bar | |

| SPEED | ≤5.0 m/sn |

| KASTAŞ NO | D(H8) | d(h8) | B(+0.2/-0.0) | r | n |

|---|---|---|---|---|---|

| K755-200-175 | 200 | 175 | 12,5 | 0,4 | 10 |

| K755-220-195 | 220 | 195 | 12.5 | 0.4 | 10 |

| K755-225-200 | 225 | 200 | 12.5 | 0.4 | 10 |

| K755-240-215 | 240 | 215 | 12.5 | 0.4 | 12 |

| K755-250-220 | 250 | 220 | 15 | 0.8 | 12 |

| K755-260-230 | 260 | 230 | 15 | 0.8 | 12 |

| K755-320-290 | 320 | 290 | 15 | 0.8 | 12 |

| K755-325-295 | 325 | 295 | 15 | 0,8 | 12 |

| K755-327.5-297.5 | 327.5 | 297.5 | 15 | 0.8 | 12 |

| K755-340-310 | 340 | 310 | 15 | 0.8 | 12 |

| K755-350-320 | 350 | 320 | 14 | 0.8 | 12 |

| K755-355-325 | 355 | 325 | 15 | 0,8 | 12 |

| K755-360-330 | 360 | 330 | 15 | 0.8 | 12 |

| K755-430-400 | 430 | 400 | 15 | 0.8 | 12 |

| K755-460-430 | 460 | 430 | 14 | 1.2 | 12 |

| K755-490-460 | 490 | 460 | 15 | 1.2 | 12 |

| K755-540-505 | 540 | 505 | 17.5 | 1.20 | 12 |

| K755-590-555 | 590 | 555 | 17.5 | 1.2 | 12 |