tel. 33 822 31 51

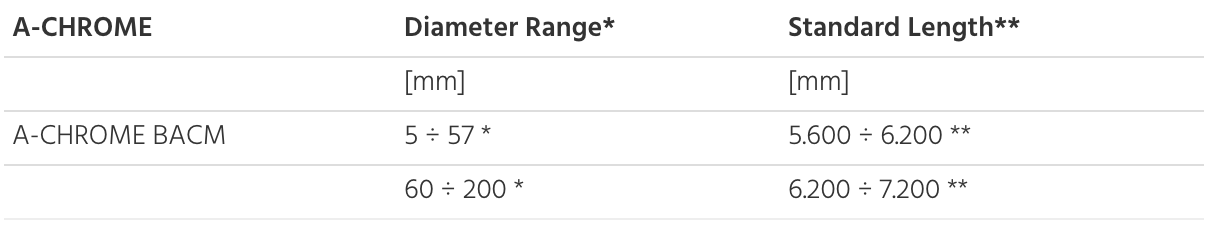

*Some diameters may be subject to a minimum quantity requested

**Lengths may vary depending on the Chroming process used

***>Other diameters, lengths/cut lengths can be provided at premium price