Chrome plated Linear Shafts – Induction Hardened – Introduction

Chrome plated linear shafts made from Cf53 Steel.Induction hardening is a form of heat treatment in which the linear shafts are heated by induction heating and then quenched. This heat treatment is increasing the hardness as well as the brittleness of the linear shafts.Induction hardened linear shafts present a soft shaft core which ensures a good resilience. Linear Shafts may appear the same for an untrained eye but the differences are notable. There are significant performance differences due to the manufacturing processes used to achieve the required standards. The linear inner race demands the highest levels of material cleanliness, surface topography, surface hardening, diameter, taper and roundness, surface finish and straightness in order to provide optimum performance at minimal maintenance and long life.The chrome surface of our Chrome plated linear shafts is giving good wear and corrosion resistance. The chroming process is giving also a good durability and helps diminishing friction.We recommend our Chrome plated linear shafts for more complex applications.

Chrome Plated Linear Shafts – Technical Properties

- Diameter Tolerance Standard for linear shafts is ISO-h7. We can also provide special tolerance at premium price.

- Length tolerance: 0/+200 [mm].

- Surface Roughness isRa = max 0.20 µm.

- Chrome Layer Surface Hardness is minimum 900 HV 0,1.

- Surface HardnessSteel-grade Cf53 IH: 62+2HRC.

- Chrome Layer thickness is minimum 10[µm], usually 15[µm].

- Standard packaging is made from plastic sleeves or paper tubes (depending on the product’s diameter).

- Special Packaging (seaworthy protected) with additional cost is made with aluminum foil or vacuum bags.

Marking in ASO HYDRAULICS & PNEUMATICS has a full trace-ability.

Each bar is marked individually on the plastic/paper tube with info about the date, product series, diameter, tolerance, resistance at saltwater spray test, heat no, production order and so on. The batch has a label with information regarding: Order no, Item no, Heat no., Steel Grade; total length of the batch, Weight, no of pieces in the batch.

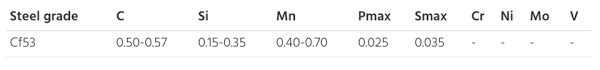

Chemical Composition

Mechanical Properties

Dimensional Properties

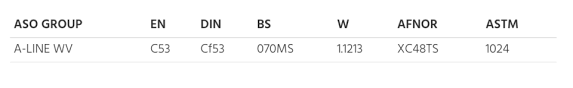

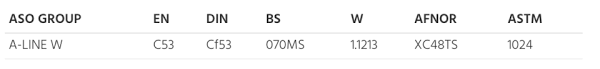

Steel grade correspondents